Aptiv and Vecna target smarter warehouse autonomous mobile robots with ML upgrade

The partners will combine Aptiv’s sensing, compute and embedded software with Vecna’s AI-driven material-handling platform.

Aptiv, an industrial-technology supplier best known for its automotive electronics, is teaming up with Vecna Robotics to build a new generation of autonomous mobile robots (AMRs) for warehouses and factories, betting that better perception and orchestration software can squeeze more productivity out of increasingly automated supply chains.

The collaboration will combine Aptiv’s sensing, compute and embedded software with Vecna’s AI-driven material-handling platform in a joint solution pitched as safer, smarter and cheaper than today’s systems.

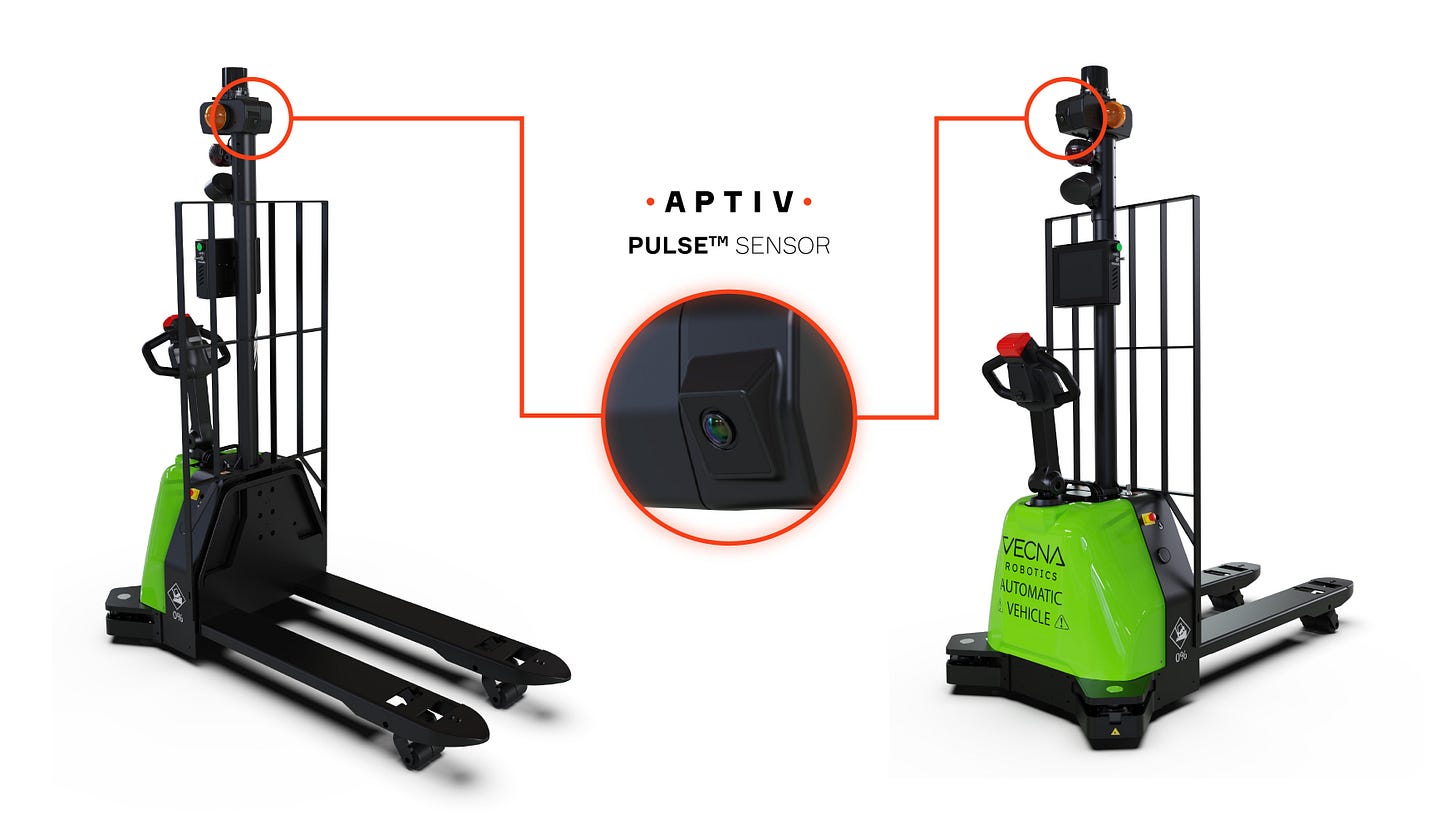

Under the deal, Aptiv’s perception portfolio — including its PULSE surround-view camera and ultrashort-range radar — will be integrated into Vecna’s AMRs, alongside machine-learning models for real-time perception and dynamic path planning in busy, mixed-traffic environments. Vecna will contribute its autonomy stack and CaseFlow workflow tools, which coordinate humans, forklifts and robots, while Aptiv supplies the underlying compute platform based on VxWorks and Wind River’s Helix virtualization technology. The companies say the result will be more flexible deployments that avoid the fixed infrastructure and brittle layouts common in older warehouse-automation projects.

Warehouse robotics has become a test-bed for the convergence of automotive-grade sensing, cloud-scale computing and generative AI, as logistics operators attempt to cope with volatile e-commerce demand, labour shortages and rising capital costs. Global spending on automation has accelerated since the pandemic, but many facilities still rely on islands of semi-automated equipment that struggle to interoperate, making orchestration software just as important as the robots themselves.

As rivals from startups to industrial conglomerates race to offer “autonomy-as-a-service”, suppliers that can bundle perception, safety and workflow optimisation into a single stack hope to lock in long-term platform relationships with fleet operators.

“Automation is transforming the way goods move through warehouses and factories, with devices that sense, think and act in real time,” said Javed Khan, executive vice-president for intelligent systems at Aptiv. “Together, we’re making automation safer, smarter, and more affordable—helping customers meet the demands of modern logistics.”

Vecna’s chief executive, Karl Iagnemma, said the tie-up would yield “more robust and cost-optimized robotic products” that cut operating costs and improve throughput while avoiding major infrastructure upgrades. Both firms pitch their approach as a way to scale deployments quickly, with Vecna’s Pivotal orchestration platform adapting to changing workflows and Aptiv’s virtualised compute designed to support different robot configurations over time.

Aptiv plans to showcase Vecna’s CPJ co-bot pallet jack at CES 2026, signalling that the robots are meant as much for marketing its software-and-sensing stack as for hauling pallets around draughty sheds.