Ati Motors hits a million missions, UBTECH humanoid changes own battery, and more

Daily brief on news from the world of automated mobile robots.

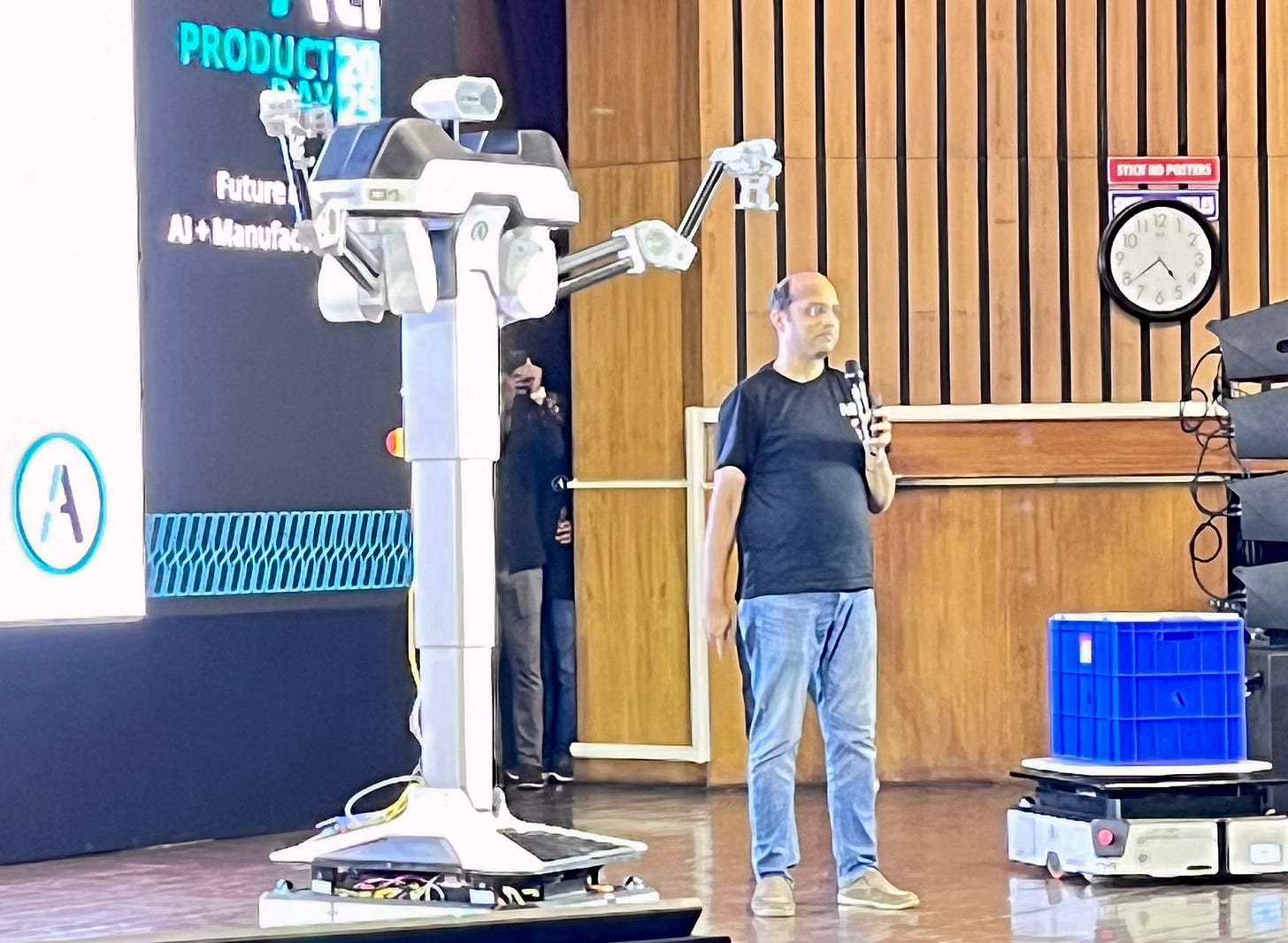

Ati Motors crosses 1 million missions, unveils Sherpa 10K and Meka

At its 2025 Products Day in Bengaluru, Ati Motors announced it has completed over 1 million autonomous missions with 95% accuracy. CEO Saurabh Chandra celebrated the company’s evolution into a full-fledged multi-disciplinary products firm, while CTO Naveen Arulselvan shared Ati’s expanded vision to orchestrate entire AMR fleets. The company unveiled the heavy-duty Sherpa 10K and the Meka humanoid prototype, now open for research partnerships, reinforcing its innovation leadership in industrial automation.

Warehouses lose 52 workdays a year to micro-inefficiencies

New research reveals that nearly two-thirds of warehouses lose up to 416 hours (about 52 workdays) annually to minor, untracked inefficiencies like device switching and repetitive checks. Despite heavy investment in digital tools, fragmented systems and poor data integration persist, with 88% of leaders admitting these small delays are not actively measured. Such micro-inefficiencies significantly impact performance as labor challenges and upgrade pressures intensify across the industry.

Cohesive Robotics launches AI-powered smart welding workcell

Cohesive Robotics has released an AI-driven Smart Welding Robotic Workcell to automate key welding processes for manufacturers facing labor shortages and complex part mixes. Powered by its Argus OS software and 3D scanning, the workcell requires no manual programming and rapidly identifies parts for MIG, TIG, or laser welding. This turnkey solution enhances accuracy and consistency, can process a variety of metals, and allows skilled operators to focus on strategic tasks instead of repetitive work.

UBTech unveils humanoid robot that autonomously swaps its batteries

UBTech’s new Walker S2 humanoid robot can autonomously replace its own battery in under three minutes, enabling true 24/7 operation without human intervention. Using a dual-battery and hot-swapping system, Walker S2 senses battery status and chooses whether to swap or recharge based on urgent tasks. This breakthrough in autonomous energy management minimizes downtime and maintenance costs, advancing continuous deployment of humanoid robots in industrial environments.

Micro case study: Advantech turns to SEER Robotics for smarter warehouse automation

Advantech improved productivity at its space-constrained US warehouse by deploying SEER Robotics’ M4 Smart Logistics Management System and rotary lifting AMRs. The system overcame dense rack layouts and dynamic, human-robot traffic with advanced pathfinding algorithms, agile rotation, and precise QR code positioning. Automated material handling replaced arduous manual tasks, reducing labor fatigue and costs while boosting order speed, rack turnover, and overall capacity. Integration with existing systems enabled a fast rollout and full logistics traceability.