Inbolt gives robots a human touch in factory bin-picking

The company says its on-arm approach generates endless grasping strategies in real time and tweaks trajectories mid-motion for precise placement.

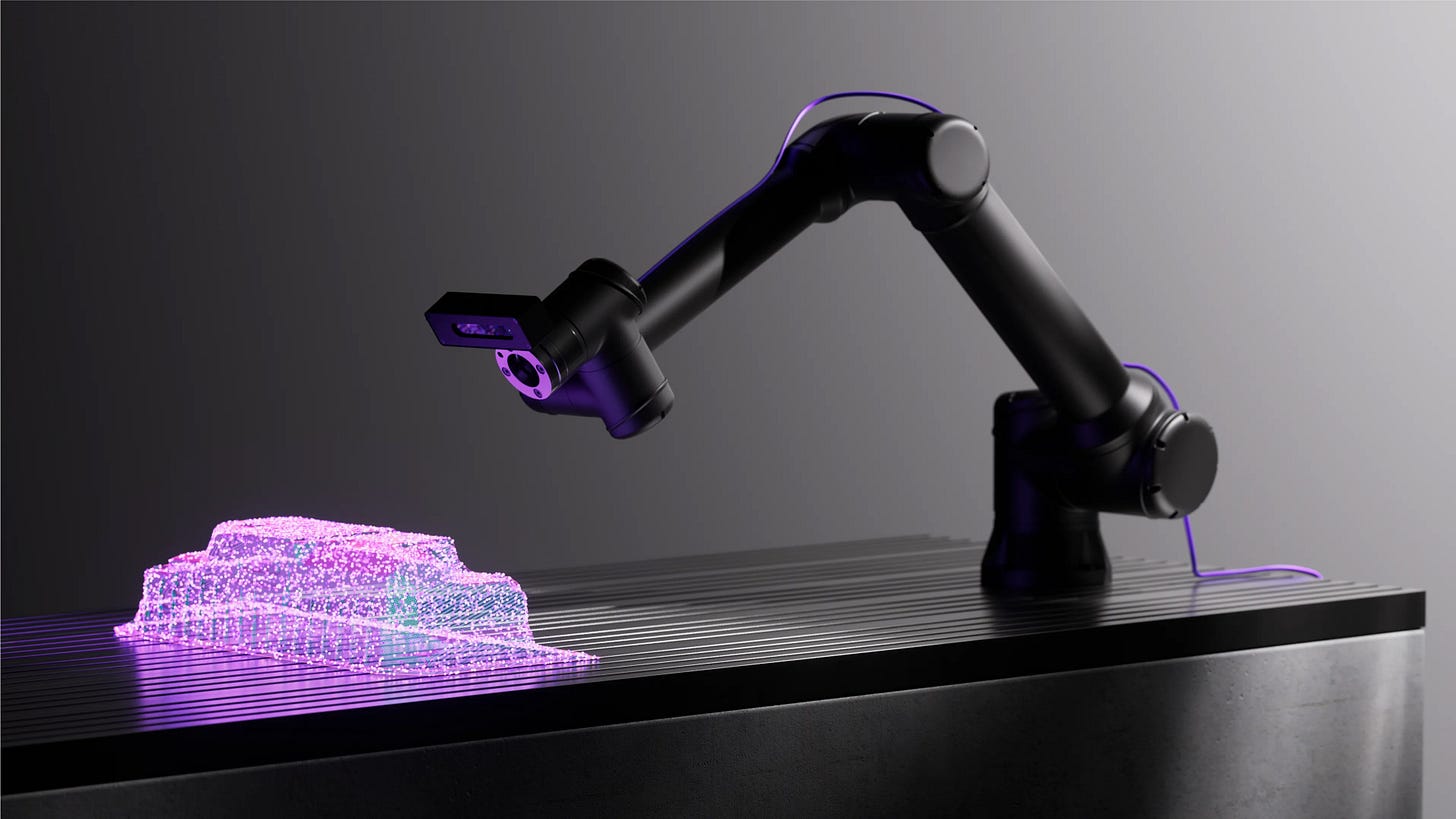

Inbolt, a Detroit-based maker of vision-guidance systems for robots, has unveiled a new bin-picking technology that mimics human dexterity. By mounting a 3D camera directly on the robot’s arm and infusing it with proprietary artificial intelligence, the system allows machines to spot, seize and position parts amid the chaos of unstructured bins — where objects lie jumbled, obscured or shifting. This promises cycle times under one second per pick and success rates up to 95 percent in live automotive production.

The innovation upends conventional bin-picking setups, which depend on costly overhead cameras, intricate calibrations and rigid grasp points prone to failure if bins budge or parts evade detection. Inbolt’s on-arm approach generates endless grasping strategies in real time, analyses objects in-hand after gripping, and tweaks trajectories mid-motion for precise placement.

Already deployed in over five factories, it slashes hardware needs to one camera per robot, easing scalability across varied bins and sites. Powered by Nvidia hardware, the system thrives on minimal computation for robust performance across part shapes.

As manufacturers grapple with labour shortages and demands for round-the-clock output, Inbolt’s advance underscores a pivotal shift in industrial automation: from brittle, vision-limited robots to adaptable “physical AI” that rivals human improvisation.

Globally, bin-picking bottlenecks hobble assembly lines in automotive, electronics and logistics, costing billions in downtime; this on-arm AI could unlock flexible, low-cost autonomy, accelerating reshoring and countering rising wages in Asia. With firms like Tesla and Foxconn scaling humanoid robots, such breakthroughs may finally tame the “last metre” of unstructured manipulation, propelling factories towards true lights-out operation.

“Traditional bin picking systems are too rigid for real factory conditions,” says Albane Dersy, Inbolt’s chief operating officer. “We designed our solution to adapt in real time, able to see, grasp, and adjust the way a human would. That level of flexibility is what manufacturers need to reach truly autonomous production.”

Key perks include resilience to moving bins, affordability sans overhead rigs, and swift integration — heralding cheaper, nimbler robotics for an era of volatile supply chains.