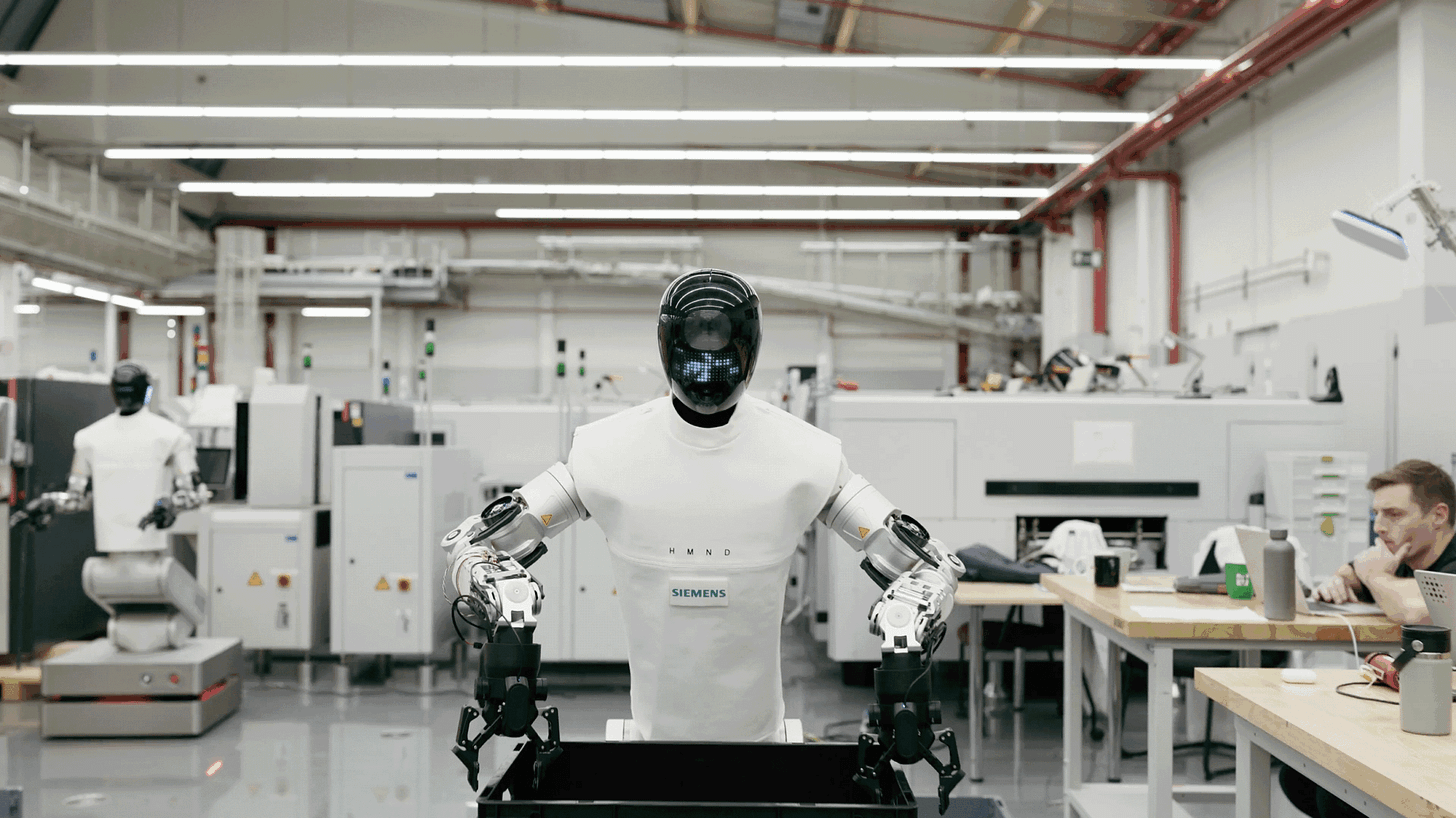

Siemens tests humanoid robots on factory floor in logistics trial

The tests were designed to see how a general-purpose robot performs in real-world conditions of industrial logistics.

Humanoid, a London-based robotics startup, has run its first live factory trial with Siemens, deploying a wheeled humanoid robot to handle box-moving chores inside one of the German group’s electronics plants. Over a two-week proof of concept in Erlangen, the HMND 01 Alpha robot shuttled plastic totes from storage stacks to a conveyor, working alongside humans in regular production.

The exercise was designed to see whether a general-purpose humanoid can take on the unglamorous but necessary work of industrial logistics, rather than the carefully fenced-off duties of traditional industrial arms. In Siemens’ tote-to-conveyor “de-stacking” task, the robot repeatedly picked containers from a pile, trundled them across the shopfloor and deposited them at a handover point for human operators until the stack was empty.

Humanoid robots have become the latest obsession in factory automation, as manufacturers hunt for flexible machines that can slip into existing layouts and workflows rather than demand greenfield redesigns. From carmakers to e‑commerce giants, companies are testing legged and wheeled bipeds in warehouses and plants, hoping they can eventually tackle varied, dull and physically taxing jobs amid labour shortages and ageing workforces. Siemens’ trial suggests that, at least for tightly defined tasks, the technology is moving from lab demo to production line experiment.

“Our focus is on creating robots that deliver measurable value in real-world settings,” Artem Sokolov, the UK company’s founder and chief executive, said in a press release. “This joint PoC with Siemens showed clear potential for practical deployment of humanoid robots. We see them move steadily toward the real world, and partnerships like this one help accelerate that transition.”

The PoC unfolded in two phases, starting with in‑house development using a physical twin of the workcell to refine performance before shifting to the live factory. In Erlangen, HMND 01 ran autonomously for stretches of more than 30 minutes, handled two tote sizes and met targets including 60 tote moves per hour, uptime above eight hours and pick‑and‑place success rates exceeding 90 percent.

Both companies bill the trial as a beginning rather than a climax. They are weighing additional logistics use cases and a broader rollout across Siemens facilities, turning the Erlangen factory — described by the group as its “customer zero” — into a test bed for what may become a new class of industrial co‑workers.